Advanced manufacturing and Vertical integration

under one roof

Machining and gear cutting

Ashot provides advanced machining, gear cutting and grinding capabilities with a full array of state-of-the-art equipment. Steel alloy processing includes stainless steel, titanium, nickel-based super alloys and composite materials.

Ashot has over 200 machining centers, including:

- 5 axis CNC milling center

- Gear cutting include hobbing, Shaping, skiving, grinding, broaching, lapping

- Turning and milling

- Deep-hole drilling and boring

- Honing

- Balancing

- Grinding & threads grinding

Heat Treatment

Our cutting-edge facility includes a full-service metallurgical laboratory that enables verification of all results in-house. We offer a complete range of heat treatment capabilities:

- Hardening and tempering (hanging, up to 2 meters)

- Carburizing and quenching

- Nitriding and carbo nitriding

- Precipitation hardening

- Induction hardening

- Press quenching

- Subzero cooling

- Annealing and Normalizing

- Stress relieving

- Solution and aging treatment (aluminum)

- Vacuum heat treatment for hardening, tempering, carburizing, solid solution heat treatment and precipitation hardening process

Chemical Processes

Ashot conducts NADCAP-approved chemical processes in-house. Our professional staff includes level-3 metallurgists, chemists, process and mechanical engineers.

Chemical processes include:

- Cadmium

- Copper

- Chrome

- Chemical conversion (Alodine)

- Passivation

- Black oxide

- Painting

- Nitriding white layer removal

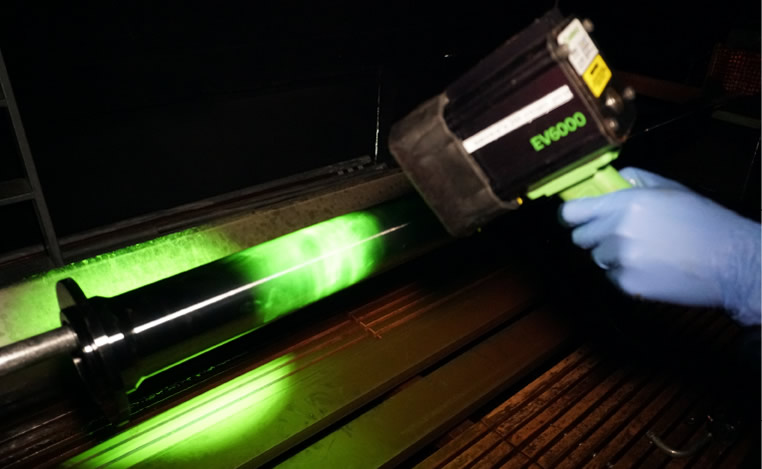

Non Destructive Tests (NDT)

Includes in-house level 3:

- Magnetic Particle Inspection (MPI)

- Fluorescent Penetrate Inspection (FPI)

- Nital (Etching inspection)

Shot peening

Shot peening includes:

- Robotic shot peening system

- Automatic shot peening

- Glass beads peening

Sintering

For more than five decades, Ashot Ashkelon Industries has been supplying tungsten-based heavy metal products to the aerospace and defense

Ashot uses the cold isostatic pressing technology and a variety of sintering techniques including deformation and heat treatment

Assembly

Ashot’s highly qualified professional teams produce, assemble, and test a variety of complex systems in our advanced facilities.

Our technicians conduct close tolerance assembly using manual, semi-automatic and robotic equipment, precision instruments, load bench facilities and test.

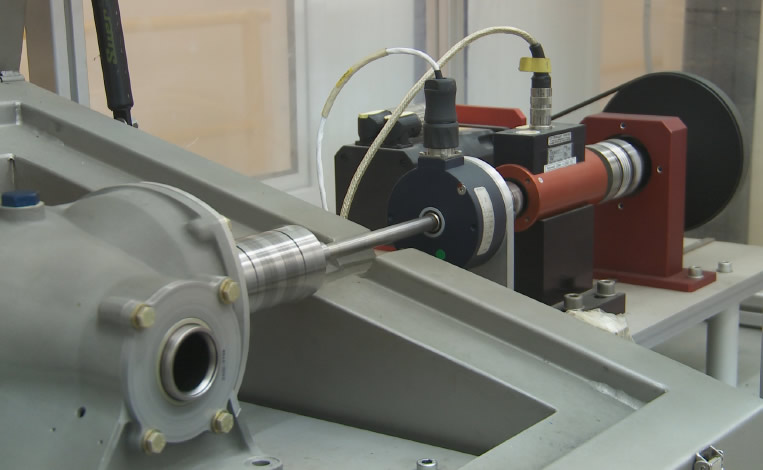

Testing

Our engineering group designs, builds and installs advanced technology solutions for testing assembled systems according to customer specifications.

- Testing facilities include testing benches and test rigs, designed and built for specific products

- Testing capabilities include gearboxes, transmissions, universal joints, stabilizers, switchboxes, PTOs, final drives, and clutch independence drives.

R&D

Ashot’s R&D department develops innovative solutions for aerospace and military assemblies and components.

Our built-to-spec product design capabilities include concurrent engineering, product development, geometric design, gear design, stress analysis material selection, and test rigs. All designs comply with aerospace standards, and some have yielded US patents.